+86 318 756 5111

+86 318 756 5111

Feb. 16, 2022

Depending on the type of mesh you choose at the time you are purchasing a sintered wire cloth will help determine the characteristics of that cloth and whether it will hold up to do the job you want it to perform. Depending on type of weave changes the functionality of the sintered wire cloth, so it is crucial that you select the correct weave for the job you are looking to get done.

There are two types of weave that are the most common. Popular mesh weaves are the plain weave and the plain Dutch weave. The plain weave is a very simple type of weave. When you examine the plain weave, you will notice that each wire crosses over and under the other, which creates a stable mesh. This type of weave is also flexible and can be used in multiple ways.

Now the plain Dutch weave is very similar to the plain weave, however the plain Dutch weave contains a much heavier wire than the other type. This helps make the plain Dutch weave much sturdier and stronger than a plain weave and is more tightly knitted together for a better filtering experience.

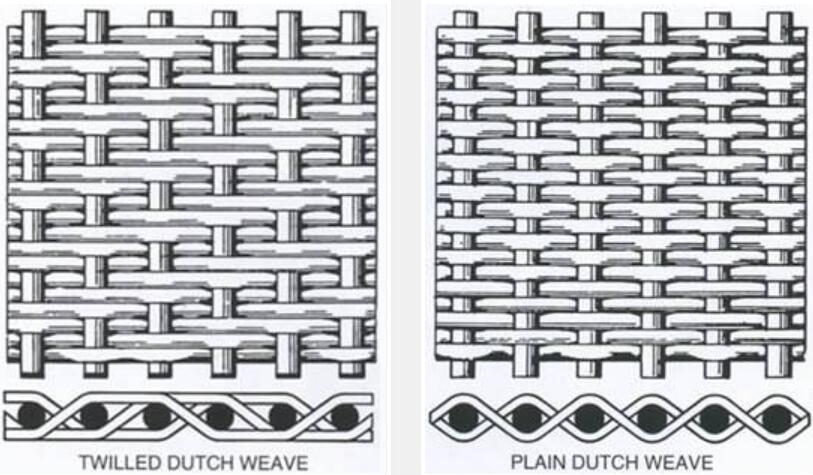

Dutch weave stainless steel wire mesh is commonly used as filter media. Plain Dutch weaves offer strength and rigidity along with fine filtration capabilities. Twilled Dutch weaves offer even greater strength and finer filtration ratings. In a twilled weave, the wires cross two under and two over, allowing heavier wires and higher mesh counts. Our micronic filter cloth is available in various meshes and weaves, including plain Dutch weave, twilled Dutch weave, and reverse Dutch weave. They are available in either T304 Stainless Steel or T316 Stainless Steel.

Dutch Weave Wire Cloth has four types of weaves, which has plain dutch woven,twill dutch woven, reverse dutch woven and five heddle weave.

Dutch woven wire filter cloth can be weaved by stainless steel wire, nickel wire, brass wire and galvanized wire.

Plain Dutch Woven Wire Cloth is woven with a large wire diameter in the warp direction and a relatively smaller wire in the shute direction. This weave has great strength and is available in wide range of micron ranges. It is primarity used to filter a wide range of liquid and slurry products.

| Specification of Plain Dutch Weave Wire Cloth | ||||

| Type | Mesh/Inch Warp x Weft | Wire Diameter mm | Weight kgs/m2 | Filtering value μm |

| PDW40 | 7*40 | 0.90*0.70 | 6.65 | 480 |

| PDW60 | 10*50 | 0.80*0.55 | 5.70 | 360 |

| PDW50 | 12*64 | 0.58*0.40 | 3.56 | 280 |

| PDW80 | 14*80 | 0.45*0.35 | 3.60 | 250 |

| PDW88 | 15*88 | 0.43*0.31 | 2.81 | 160 |

| PDW100 | 16*100 | 0.40*0.28 | 2.70 | 200 |

| PDW110 | 24*110 | 0.35*0.25 | 2.32 | 125 |

| PDW140 | 25*140 | 0.30*0.20 | 1.96 | 100 |

| PDW150 | 30*150 | 0.25*0.18 | 1.68 | 80 |

| PDW180 | 35*180 | 0.23*0.15 | 1.47 | 70 |

| PDW200 | 40*200 | 0.20*0.14 | 1.30 | 63 |

| PDW220 | 45*220 | 0.18*0.125 | 1.22 | 56 |

| PDW250 | 50*250 | 0.15*0.11 | 0.95 | 50 |

| PDW280 | 50*280 | 0.14*0.10 | 0.84 | 45 |

| PDW300 | 60*300 | 0.14*0.09 | 0.80 | 40 |

| PDW320 | 65*320 | 0.12*0.085 | 0.75 | 36 |

| PDW350 | 70*350 | 0.11*0.08 | 0.70 | 32 |

| PDW400 | 80*400 | 0.125*0.063 | 0.77 | 42 |

| PDW700 | 80*700 | 0.125*0.04 | 0.60 | 40 |

| PDW1200 | 100*1200 | 0.063*0.023 | 0.27 | 23 |

Twill Dutch Weave Wire Cloth is the larger diameter warp wires successively pass over and under the lighter diameter shute wires. Each pass of the shute wires shifts the over and under movement one wire. The shute wires are driven up close, resulting in a tightly woven filter cloth with tapered or wedge shaped openings.

| Specification of Twill Dutch Weave Wire Cloth | ||||

| Type | Mesh/Inch Warp x Weft | Wire Diameter mm | Weight kgs/m2 | Filtering value μm |

| TDW150 | 20*150 | 0.45*0.355 | 6.02 | 101 |

| TDW200 | 20*200 | 0.355*0.28 | 4.58 | 118 |

| TDW250 | 30*250 | 0.28*0.020 | 3.41 | 77 |

| TDW500 | 50*500 | 0.14*0.112 | 1.83 | 47 |

| TDW700 | 80*700 | 0.11*0.08 | 1.38 | 28 |

| TDW900 | 100*900 | 0.10*0.60 | 1.06 | 22 |

| TDW400 | 120*400 | 0.10*0.071 | 0.86 | 35 |

| TDW1100 | 125*1100 | 0.08*0.05 | 0.88 | 18 |

| TDW1200 | 150*1200 | 0.07*0.045 | 0.8 | 16 |

| TDW1400 | 165*1400 | 0.063*0.04 | 0.73 | 15 |

| TDW1400 | 200*1400 | 0.07*0.040 | 0.80 | 12 |

| TDW1500 | 160*1500 | 0.063*0.036 | 0.67 | 14 |

| TDW1800 | 200*1800 | 0.05*0.03 | 0.53 | 11 |

| TDW2000 | 200*2000 | 0.05*0.028 | 0.55 | 12 |

| TDW1900 | 250*1900 | 0.04*0.028 | 0.51 | 8 |

| TDW2200 | 280*2200 | 0.035*0.025 | 0.42 | 6 |

| TDW2300 | 320*2300 | 0.033*0.024 | 0.41 | 5 |

| TDW2300 | 325*2300 | 0.035*0.025 | 0.45 | 5 |

| TDW2800 | 400*2800 | 0.025*0.020 | 0.36 | 3 |

| TDW3500 | 500*3500 | 0.025*0.015 | 0.30 | 5 |

Reverse Dutch Weave Wire Cloth is a very strong woven product.This mesh is ideal for making filter belts, and applications where fine filtration and great strength are required.

Properties: Very good flow rates, small pressure drop; surface is slightly structured.

Applications: Pressure and vacuum filters; filter candles.

| Specification of Reverse Dutch Weave Wire Cloth | ||||

| Mesh/Inch Warp x Weft | Wire Diameter Warp x Weft mm | Wire Diameter Warp x Weft inch | Absolute Filter rating μm | |

| 63 x 18 | 0.40 x 0.60 | 0.0157 x 0.0236 | 220 | |

| 107 x 20 | 0.24 x 0.60 | 0.0094 x 0.0236 | 210 | |

| 130 x 35 | 0.20 x 0.40 | 0.0079 x 0.0157 | 80 | |

| 132 x 16 | 0.24 x 0.60 | 0.0094 x 0.0236 | 200 | |

| 132 x 32 | 0.20 x 0.40 | 0.0079 x 0.0157 | 105 | |

| 140 x 40 | 0.19 x 0.38 | 0.0075 x 0.015 | 100 | |

| 170 x 40 | 0.20 x 0.45 | 0.0079 x 0.0177 | 130 | |

| 180 x 120 | 0.088 x 0.10 | 0.0035 x 0.004 | 75 | |

| 200 x 120 | 0.08x 0.10 | 0.0031 x 0.004 | 70 | |

| 175 x 40 | 0.15 x 0.38 | 0.0079 x 0.0157 | 70 | |

| 175 x 50 | 0.15 x 0.30 | 0.0059 x 0.012 | 60 | |

| 290 x 75 | 0.09 x 0.20 | 0.0035 x 0.0079 | 55 | |

| 600 x 100 | 0.04x 0.14 | 0.0157 x 0.0055 | 25 | |

| 615 x 130 | 0.04 x 0.13 | 0.0157 x 0.0051 | 22 | |

| 615 x 102 | 0.04x 0.16 | 0.0157 x 0.0063 | 42 | |

| 625 x 133 | 0.04 x 0.13 | 0.0157 x 0.0051 | 17 | |

| 720 x 150 | 0.036 x 0.10 | 0.0014 x 0.0039 | 17 | |

| 850 x 155 | 0.03 x 0.10 | 0.0012 x 0.004 | 10 | |

The plain weave and Dutch plain weave are just two types of mesh weaves. Give us a call today and we can help you determine the right type of mesh weave for your project.

Previous: shaker screen constructure

Navigation

TEL.: +86 318 756 5111

Fax: +86 318 753 7111

E-mail: sales@hengyingwirecloth.com

Add: NO.17 Jing Wu Road, High and New Tech Development Zone, Anping County, Hebei Province, China.

Follow Us