+86 318 756 5111

+86 318 756 5111

Jun. 10, 2022

Drilling fluid vibrating screen is the most used solid control equipment in oil drilling mud purification system, using excitation motor, suitable for oil drilling fluid purification single link, double link or triple link, at the same time, drilling fluid vibrating screen can also be used in the bottom flow vibrating screen of mud cleaner. With high vibration strength, large screening area, adjustable screen box angle, compact structure and excellent performance, drilling fluid vibrating screen is widely used in oil drilling, non-excavation horizontal directional crossing, coal bed methane drilling, shale gas drilling, river sludge environmental protection and other mud purification treatment fields.

Vibrating screen in the process of use will appear a variety of different problems, which for the emergence of running slurry situation, through a case-by-case analysis and summary, there are mainly the following aspects of the reasons.

Vibrating screen running slurry

● High solid phase content in the drilling fluid.

● High specific gravity of mud.

● High mud viscosity.

● Drill chips dispersion.

● low vibration force of the vibrating screen.

● High mesh size of the screen.

● small effective area of the screen.

● The choice of vibration trajectory, which determines the mud transport speed.

● too small adjustment of screen box elevation angle.

● Wrong direction of vibration motor rotation.

● the amount of slurry supply is too large than the maximum processing of the vibrating screen.

● screen mesh mesh clogging, after the use of water is not flushed flush screen in time to cause mud dry solid.

● mud performance changes, did not adjust the percentage of vibrating motor eccentric block in time accordingly.

● installation problems: improper installation of the direction and position of the inlet port of the vibrating screen.

The handling capacity of each vibrating screen is 50L/s. This is because the conditions of the handling capacity test are according to the national standard: 60 mesh mesh is selected, and the test is carried out in the mud with a specific gravity of 1.8 aggravated mud, and the mud viscosity is the mud containing river sand with different particle sizes. Due to the rapid drilling of the surface layer, which produces a large amount of solid phase occupying the effective screen area, the vibrating screen cannot be used in the shallow section of the well with a fine screen. Therefore, screens with larger holes should be used at the beginning of drilling, while finer screens are gradually used as the drilling depth increases.

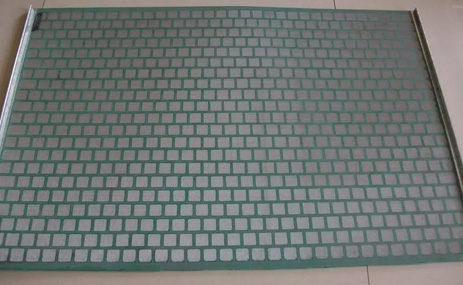

Vibrating screen mesh

Since the drug added to the drilling fluid is not fully dissolved and glued on the screen, serious slurry running can occur at this time. You should wait for the drug to be fully dissolved before using it, or use a screen with larger holes. In another case, when drilling to the loose sand-bearing rock layer or flowing sand layer, the sand particles are easily stuck in the holes of the shaker screen mesh, causing the phenomenon of screen blockage. Therefore, several different mesh sizes should be tested to reduce the blockage phenomenon.

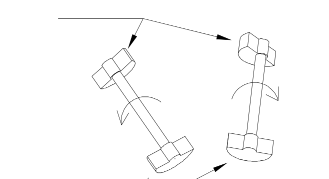

Firstly, remove the vibrator shield and check whether the eccentric block of both motors rotates to the outside. Secondly, if the steering is wrong, please change any two-phase wires in the power supply of the electric control box. Wrong-way one (two motors rotate towards the inner side), although it can also exclude the drill chips outward, but the speed is slow; wrong way two (two motors rotate in the same direction), the vibration force is very small, basically not discharging sand and not dealing with mud.

Motor turning

The larger the vibration amplitude is generally also relatively larger processing capacity; the factory vibration force is adjusted to 90%. If the slurry running situation occurs, you can align the inner and outer eccentric block angle, then the vibration force is 100%. (At this time, the processing capacity of mud only increases about 15%)

Motor

Vibration force adjustment

The vibrating screen with hook side screen structure, the screen surface on both sides is lower than the middle, the mud is easy to flow to both sides and run away, it should ensure that the mud enters the screen frame from the middle. At this time, two programs can be used. One is to adjust the front spring seat to appropriately raise the angle of the front of the screen box; the second is to adjust the position of the flap in the extension slot to control the liquid flow distribution.

Elevation angle adjustment device

The main reason for running slurry in the process of drilling fluid vibrating screen is sometimes caused by one of the aspects, but sometimes it is caused by a multifaceted outbreak, so we hope that users can analyze the causes and troubleshoot timely and accurately to ensure the normal operation of the equipment.

Previous: Methods of selecting well screen

Navigation

TEL.: +86 318 756 5111

Fax: +86 318 753 7111

E-mail: sales@hengyingwirecloth.com

Add: NO.17 Jing Wu Road, High and New Tech Development Zone, Anping County, Hebei Province, China.

Follow Us